Every facility must be knowledgeable about proper procedures for drain sanitation. Slot Drain Systems are designed to meet requirements set forth by the USDA and FDA to help prevent bacterial growth in your facility.

Slot Drain® is installed worldwide in food safe facilities, undergoing regular USDA inspections. Several facilities are SQF certified with an “excellent” rating.

Drain Sanitation Solutions that will help prevent Bacteria

Drainage Designs

That are labeled food grade or food safeThat have built-in slopes to prevent standing water

That have smooth edges and rounded corners will prevent Listeria and other pathogens

That have sealed connections or fully welded joints will prevent the growth of Listeria in non-accessible areas of the drain

Drainage Materials

That are smooth or brushed to deter organisms from attaching and growing along the drain channel

Drainage Cleaning

Is automated or aided by CIP (clean in place) systems. See below for an ebook on CIP in drainage systems.

Is easy to visually inspect or access to ensure cleanliness

That has accessories like pits, strainers or grease interceptors to allow for environmentally friendly waste removal

USDA Plumbing Requirements and Slot Drain®

VIEW THE USDA GUIDE

Plumbing systems must be installed and maintained to:

-

Slot Drain® can carry up to 27 gallons of water per minute (per foot of slot) or 270 gpm in each ten foot section.

- Slot Drain channels are built with a 0.5% built-in slope. The concrete surrounding Slot Drain is a low-maintenance and lost cost two-sloped floor. Both these concepts allow for water to drain away from the establishment to prevent standing water.

- The Stainless Steel Slot Drain® is made of 100% stainless steel and can handle extreme temperatures and harsh chemicals when required. The smooth stainless steel prevents the growth of bacteria.

- Slot Drain is applicable where floor or ground surfaces are subject to fluids, or have frequent cleaning requirements.

- Slot Drain has mechanically-locking joints and bolt-together flanges to prevent fluids from leaking, dripping or contaminating their surroundings.

- Slot Drain is a one-piece, built-in, sloped, open floor drain/surface drain system that is comparable in price yet superior in many way.

- Slot Drain® catch basin is 100% stainless steel has a standard 4" or 6" outlet for easy connection to the sewer system / p-trap.

USDA Drainage Sanitation Requirements

- Dry Clean

- First Rinse

- Soap and Scour

- Post Rinse and Inspect

- Remove and Assemble

- Pre-op

- Sanitize

Slot Drain Cleaning Systems

Slot Drain Systems has designed specific cleaning systems to adhere to drain sanitation requirements. Slot drain also saves our clients time, money and effort during their cleaning procedures.

Regular Cleaning – Cleaning Paddle & Brush

The cleaning paddle is the simplest way for regular drainage cleaning. You just insert the paddle, twist 90 degrees and move it along the drain to clear the debris.

Frequent Cleaning – Flush Flo

This system is connected to a water line and can be operated with a timer or flushed manually. You can open a valve to let water flush and clean the drain, or set a timer to clean the drain automatically. The Flush Flo system is highly recommended for the food and beverage processing industry.

Clean in Place (CIP)

CIP is a method of cleaning that is commonly used in hygiene critical industries. Slot Drain® CIP functionality allows the entire system to be sanitized from within. It is ideal for facilities that require frequent cleaning and sanitation.

Strainer Basket

The strainer basket’s .5-inch perforated holes trap stones, keys, rings and other items that are smaller than the slot opening. Made of stainless steel, it is designed to last for the life of your system.

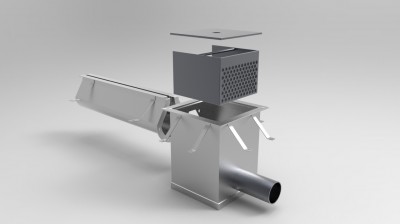

Catch Basin

Catch basins are designed to be receptacles for retrieving any items that may inadvertently go into the slot. Basins come in 8×8″, 12×12″ or 24×24″ wide and are typically 20″ deep. The basins come with a reinforced cover made of T304 stainless steel with rebar tie-ins and can withstand heavy traffic loads.

LEARN MORE ABOUT SLOT DRAIN CLEANING ACCESSORIES

Slot Drain is designed to be cleaned Easily and Effectively

Food Safe Drains contains several articles for food and beverage facilities researching the best types of drain systems for their applications.